Continuous Improvement Training

Vector Solutions’ Continuous Improvement Training provides workers with the knowledge and tools to drive efficiency, improve safety, and reduce waste. Designed for maintenance technicians, equipment operators, supervisors, and training leaders, these 45+ expert-led online courses help organizations implement Lean practices, enhance equipment reliability, foster a culture of ongoing improvement, and empower workforces to think Lean, solve problems, and boost productivity across operations.

Speak to an Expert

Learn more about our courses, get pricing, and see our platform.

Discover Some of Our Most In-Demand Courses

- Applied Vibration Analysis: Analyzing Bearing Vibrations

- Applied Vibration Analysis: Analyzing Fan Vibrations

- Applied Vibration Analysis: Analyzing Gear Vibrations

- Applied Vibration Analysis: Analyzing Motor Vibrations

- Applied Vibration Analysis: Analyzing Pump Vibrations

- Applied Vibration Analysis: Analyzing Spectral Data

- Applied Vibration Analysis: Collecting Spectral Data

- Applied Vibration Analysis: Introduction

- Asset Condition Management: Alignment and Balancing Training

- Asset Condition Management: Motor Testing

- Asset Condition Management: Setting Up an Oil Analysis Program

- Asset Condition Management: Vibration Analysis Training

- 5S Methodology

- Essentials of Lean Manufacturing

- Essentials of Six Sigma

- Industrial Housekeeping

- Lean Manufacturing: Continuous Improvement and the PDCA Cycle

- Lean Manufacturing: Determining the Voice of the Customer

- Lean Manufacturing: Kaizen

- Lean Manufacturing: Kanban

- Lean Manufacturing: Poka-Yoke

- Lean Manufacturing: Pull Systems

- Lean Manufacturing: Standardized Work

- Lean Manufacturing: Value and Waste

- Lean Manufacturing: Value Stream Mapping

- Lean Manufacturing: Visual Management

- The 5S System: 5S for Safety - New Eyes for the Shop Floor

- The 5S System: An Introduction to 5S

- The 5S System: Set in Order and Shine

- The 5S System: Standardize and Sustain

- The 5S System: Workplace Scan and Sort

- Understanding Facility Costs

Frequently Asked Questions (FAQs) About Continuous Improvement Training

What is continuous improvement?

Continuous improvement is a structured approach to identifying inefficiencies and enhancing processes, equipment, and workflows over time. It involves Lean practices, reliability methods, and proactive problem-solving to create long-term operational gains.

Who needs this training?

Any organization focused on reducing waste, improving productivity, and ensuring safe, reliable operations benefits from continuous improvement training. It is particularly valuable for industries where downtime, defects, or inefficiencies impact performance and safety, and is often used by maintenance technicians, machine operators, production supervisors, reliability engineers, and training managers who play a direct role in improving processes and outcomes.

Does this training support compliance or certifications?

Yes. While the courses primarily focus on operational excellence, courses also support compliance with industry standards and reinforce best practices that align with continuing education requirements for license professionals. For example, accredited courses can be applied toward continuing education hours for Certified Maintenance and Reliability Professional (CMRP) and Certified Maintenance and Reliability Technician (CMRT) recertification through the Society for Maintenance and Reliability Professionals (SMRP).

What course topics are included?

The online training covers Lean manufacturing and 5S, Total Productive Maintenance (TPM), quality and reliability fundamentals, root cause failure analysis (RCFA), Plan–Do–Check–Act (PDCA) cycle, vibration analysis, and more. Each course is designed to be practical, accessible, and directly applicable to daily operations.

How can teams access this training?

Courses are delivered online through Vector Solutions’ LMS platform, allowing teams to learn anytime, anywhere. Managers can track progress, assign modules, and customize training to align with organizational goals.

How is this continuous improvement training delivered?

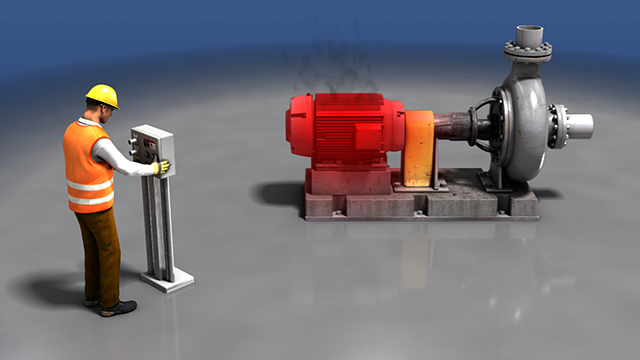

Vector Solutions delivers continuous improvement training through engaging 3D animations, scenario-based lessons, and interactive modules that help learners apply concepts to real-world situations. Courses are available in 40+ languages, making it easy for teams to access and understand critical content. This modern, flexible approach provides training is not only accessible anytime, anywhere, but also impactful in driving knowledge retention and operational improvement.